Many different sizes lathe turning machines

Big brands you chosed are available, we could get distributor from factories!

Contact with us to check right machines in our catalog!

NO 1, CNC SIWSS LATHE TURNING MACHINES

Swiss CNC Lathe Machine is called core-type CNC lathe, it can also be referred to as moving headstock type CNC automatic lathe, economical turning-milling compound machine tool or slitting lathe. It belongs to precision processing equipment, which can complete compound processing such as turning, milling, drilling, boring, tapping, and engraving at the same time. It is mainly used for batch processing of precision hardware and shaft special-shaped non-standard parts.

Swiss CNC Lathe Machine has a qualitative leap in machining efficiency and machining accuracy than CNC lathes. Thanks to the dual-axis arrangement of tools, the machining cycle time is greatly reduced. By shortening the tool exchange time between the gang tool and the opposed tool station, multiple tools Table overlap function, effective axis movement overlap function of thread chip, direct spindle indexing function during secondary processing, realize the shortening of idling time. Chip cutting tools have always been processed on the clamping part of the spindle and the workpiece to ensure constant processing accuracy. The maximum processing diameter of the core machine on the market is 38mm, which has a great advantage in the precision shaft processing market. This series of machine tools can be equipped with automatic feeding devices to realize fully automated production of a single machine tool, reducing labor costs and product defect rates. It is very suitable for mass production of precision shaft parts.

Widely used in instruments and meters, clocks, cameras, home appliances, medical equipment, hardware, communication electronics, automobiles, military industry, aerospace and other fields.

Type

Swiss

CNC Lathe Machine

Max processing OD range

Φ3-12mm, Φ3-22mm, Φ3-25mm, Φ8-32mm or otehrs

Max processing length at one time

180mm

Maxi spindle drilling diameter

Φ10mm

Maxi spindle tapping diameter

M10

Side tool max drilling diameter

Φ8mm

Side tool max tapping diameter

M6

Main and sub spindle C axis indexing

0.001°

Z axis travel distance of main spindle

280mm

Spindle run-out tolerance

≤0.004mm

X/Y/Z repeated accuracy

≤0.002mm

X/Y/Z position accuracy

≤0.003mm

Min setting unit in system

0.001mm

Tools

Buy separately

Coolant system

yes

Air supply

Above or equals to 0.4 Mpa

Powe supply

380V, 50HZ, 3 Phase, or customized

Measure(L*W*H)

1720*1040*1690

Weight

1300KG

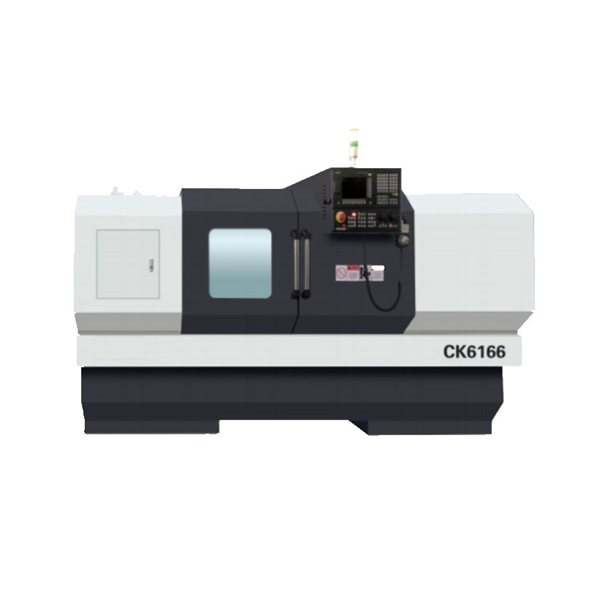

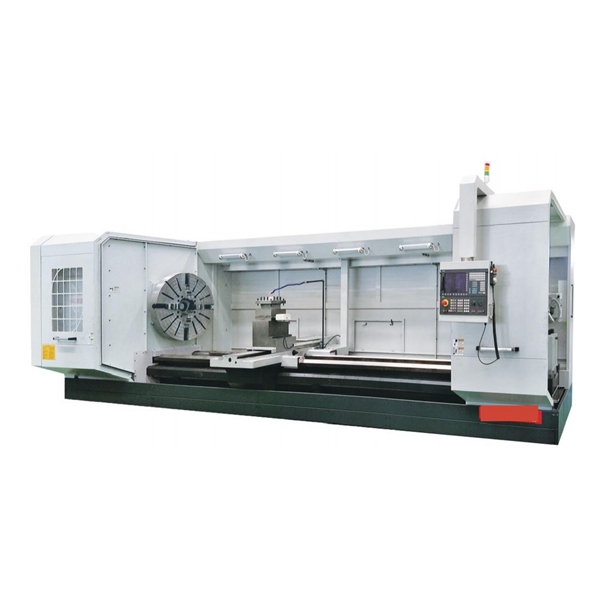

NO 2, CNC LATHE TURNING MACHINES

A new company established after restructuring a large state-owned backbone enterprise with a history of more than 110 years. At present, the company can provide users with complete sets of cylindrical gear processing equipment except gear grinding machines. The product categories cover 7 categories and 15 series, including ordinary lathes, CNC lathes, CNC milling machines, machining centers, gear hobbing machines, universal gear shaving machines, and gear honing machines. It mainly serves automobile and motorcycle manufacturers, large gear processing industries, hardware tool industries, and higher vocational education fields, and its products are exported to more than 40 countries and regions.

|

|

|

LCK32/ LCK36 |

|

CAPACITY |

Max. swing over bed |

Φ320mm/Φ360 mm |

|

Max. swing over carriage |

Φ140mm/Φ190mm |

|

|

Max. Cutting legth |

330mm |

|

|

Rail width |

260mm |

|

|

SPINDLE |

Spindle nose |

A2-5/ A2-6 |

|

Spindle bore |

Φ56mm/Φ62mm |

|

|

Taper of spindle bore |

|

|

|

Chuck |

6”/6”or 8” |

|

|

Range of spindle speed |

100-4000rpm |

|

|

FEEDS |

X a-xis travel |

350mm |

|

Z a-xis travel |

420mm |

|

|

X/Z Rapid speed |

16/18m/min |

|

|

CARRIAGE |

Station of tool carrier |

4 or 6,可选排刀 |

|

Max. section of tool |

20×20mm |

|

|

TAILSTOCK |

Stroke of tailstock sleeve |

No |

|

Diameter/Hole of tailstock sleeve |

No |

|

|

MOTOR |

Main motor power |

2.2kW/4kW or 5.5kW |

|

Coolant pump power |

180W/250W |

|

|

DIMENSION |

Overall dimensions L×W×H |

2000×1400×1500mm |

|

Parking size L×W×H |

2200×1650×1800mm |

|

|

WEIGHT |

Net weight |

1400kg/1750kg |

|

Gross weight |

1650kg/2050kg |

|

|

|

CK6132×500/750/1000 |

CK6432×500/750 |

|

CAPACITY |

Max. swing over bed |

Φ320mm |

Φ360mm |

|

Max. swing over carriage |

Φ150mm |

Φ150mm |

|

|

Max. Cutting legth |

500/750/1000mm |

500/750mm |

|

|

Rail width |

206mm |

260mm |

|

|

SPINDLE |

Spindle nose |

A2-5 |

A2-6 |

|

Spindle bore |

Φ40mm/ 可选 Φ56mm |

Φ60mm |

|

|

Taper of spindle bore |

MT5 |

MT6 |

|

|

Chuck |

6” |

8” |

|

|

Range of spindle speed |

150-2500rpm |

150-2500rpm |

|

|

FEEDS |

X a-xis travel |

180mm |

350mm |

|

Z a-xis travel |

500/750/1000mm |

500/750mm |

|

|

X/Z Rapid speed |

4/7m/min |

4/7m/min |

|

|

CARRIAGE |

Station of tool carrier |

4 or 6 |

4 or 6 or 8,可选排刀 |

|

Max. section of tool |

20×20mm or 16×16mm |

20×20mm |

|

|

TAILSTOCK |

Stroke of tailstock sleeve |

100mm |

100mm |

|

Diameter/Hole of tailstock sleeve |

Φ32mm/MT3 |

Φ50mm/MT4 |

|

|

MOTOR |

Main motor power |

2.2kW or 3.7kW |

3.7kW |

|

Coolant pump power |

120W |

120W |

|

|

DIMENSION |

Overall dimensions L×W ×H |

1600/1920/2100×1120×1750mm |

1740/2000 × 1210 × 1650mm |

|

Parking size L×W ×H |

1815/2120/2300×1300×2000mm |

1960/2230 × 1410 × 1990mm |

|

|

WEIGHT |

Net weight |

800/900/1050kg |

1275/1450kg |

|

Gross weight |

950/1050/1200kg |

1450/1600kg |

|

Main Technical data |

|

CK6136H |

CK6140H |

|

Max. swing over bed |

mm |

360 |

400 |

|

Max. turning diameter over the cross slide |

mm |

192 |

225 |

|

Max. length of workpiece |

mm |

650(标准机)/ 900 |

|

|

Spindle through bore |

mm |

58 |

|

|

Cone of the spindle bore |

|

A-6 |

|

|

Power of the main drive motor |

KW |

5.5 |

|

|

Spindle speeds |

rpm |

50-2000 (独立主轴independent spindle running speed) |

|

|

Rapid travel speed, X/Z |

mm/min |

4000/6000 |

|

|

No. of tool positions on the turret |

|

4(标准standard)/6(任选option) |

|

|

Diameter of the tailstock quill |

mm |

55 |

|

|

Working travel of the tailstock quill |

mm |

120 |

|

|

Cone of the tailstock quill bore |

mm |

莫氏4(Morse Taper No.4) |

|

|

Net weight |

kg |

1500 |

|

|

Overall dimensions (L×W×H) |

mm |

2200×1300×1750(650) |

|

Lily

Lily